So, with my excitement over finding this new wonderful material I thought I would make up a quick how-to post for anyone who doesn’t yet know the joys this product can bring.

This is HEATnBOND. I have no brand bias yet since this was my first experience with the product, but I have no complaints. I made sure to get the sewable style as I knew I’d have to stich seams together. It cost around $6.99/yd. retail, which is quite steep in my opinion, but I had a 40% off coupon so it wasn’t so bad in the end. It comes in 21-22” bolts just like interfacing. *** In fact, it was thrown in with the interfacing at my local fabric store ***.

As a slight side note: Does anyone else get irritated that interfacing (and now this product) only comes in single layer 22” strips instead of 45” bolts like every other fabric? I always get cranky when I to buy twice the yardage of interfacing as fashion fabric.

Any who, back on subject. First things first. Measure the pattern piece you’ll need to have plasticized.

I had already cut out the major pieces for the inner bag, but I still needed to make the inside of the drawstring opening. So that’s what I measured.

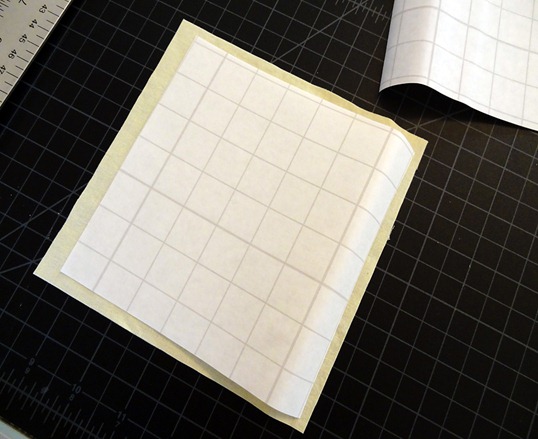

I’m a bit of a worrier so I decided to cut out a 5”x5” piece of vinyl to make doubly sure I had clearance. You don’t have to do this though. ***You can actually just cut the pattern piece out directly from the vinyl.***

Now’s the time you’ll also want to cut out your fashion fabric.

Tip:

Cut out your fashion fabric .5”-1” bigger than your vinyl piece. This will make it easier to center the vinyl on your fabric later without any bits hanging off the edge. The first time you see your iron touch this product you’ll realize why this is an important step. Let's just say it took me a good 10 minutes to get my iron clean.

Now that you have your fabric and vinyl cut out, you’ll want to place the fabric right side up. Make sure to clean off any fuzz balls or threads. You’re about to laminate it so you want it looking as good as possible!

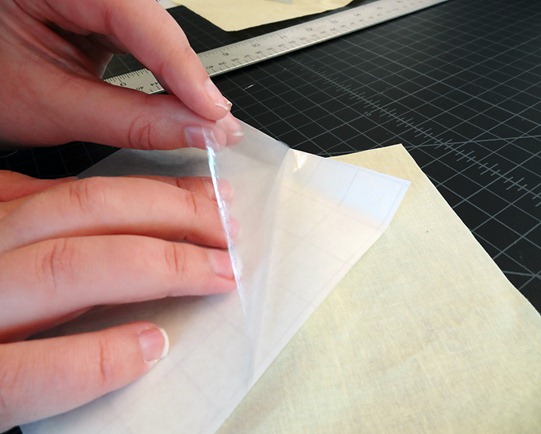

Once finished, go ahead and peal off the vinyl's paper backing.

The corners are sometimes stubborn to get started, but if you just rub it between your thumb and forefinger it will come a loose. Don’t throw this paper away though, we will need it later!

Now go ahead and place the vinyl sticky side down onto the right side of your fabric. The HEATnBONDs ‘sticky’ side was of relatively low tac. This was great because it was really easy to reposition when I made a mistake.

Smooth out all the bubbles and get ready to iron!

Following the directions that came with your iron on vinyl set your iron to the indicated temperature and wait for it to heat up. *** Mine said to set it on medium with no steam ***

Now, this step is important. When preparing to ironing on the vinyl side of the fabric, make sure to place the paper backing you peeled off between the fabric and your iron. If you put the iron directly on the vinyl it will instantly melt into a globby mess. *** I just nicked a corner of the outside, but the speed of meltage was really quite shocking @_@ *** So I repeat, DO NOT PLACE YOUR IRON DIRECTLY ON THE VINYL.

I saved a larger piece of the paper backing from an earlier piece I’d made. This was awesome because it ‘ment I didn’t have to perfectly line up the fabric with the paper every time.

Read your brands directions to know how many seconds it says to heat each side. I think mine said 8, but I didn’t follow it to the T. I pretty much just treated it like iron on interfacing.

Now you can flip the fabric over and iron the other side in the same way. Because you *wisely* cut the vinyl smaller than your fashion fabric, you can iron directly on the back of the fabric without worry.

You’re all done! Now you have water resistant fabric in whatever color or pattern you want! You can sew this just like normal fabric to create whatever shape you need.

*** Note: I would be a bit more conservative with your fabric pins now. Because your fabric has a plastic layer it won’t recover from small punctures anymore ***

This product has opened up the awesome ability to make PurseBud diaper bags without being limited to any specific color or pattern that my local fabric stores have on hand. I can use any color I want!

I finished the Winnie-the-Pooh bag yesterday afternoon and, despite my reservations about the characters, it turned out super cute.

My favorite part of this bag, aside from my love of its waterproof innards, is the fact that it’s convertible from an over the shoulder bag to a backpack. This allows for both arms to be completely free when needed. It also has the 6 outer pockets hidden inside the leaves and petals just like the standard sized PurseBuds. That means lots of places to stick toys,clothes, diapers, and bottles!

Hopefully my moms coworker loves it as much as I do ^_^.

Situs sabung ayam pw

ReplyDelete